How can I Change the Mold Quickly?

How can I Change the Mold Quickly?

We often hear that the transfer time of an ABS Plastic Tube Core Supplier is

very fast, but comparing with our own situation, it seems that it will never

reach that level. I think we are all misunderstood. A company's promotion is

usually a limit operation that is carefully prepared and fully guaranteed by

various resources. But propaganda can do it, indicating that after various

improvements, there is an opportunity to increase the time to turn molds. On the

front and back sides of the machine, the two technicians moved the mold up,

tightened the four yards of the front and back molds, and inserted a set of

cooling water in the front and back molds to complete the mold turning.

Generally, in this case, it is not necessary to change the material, and the

mold frame can be started to produce. So how should we control the transfer time

of the big mold?

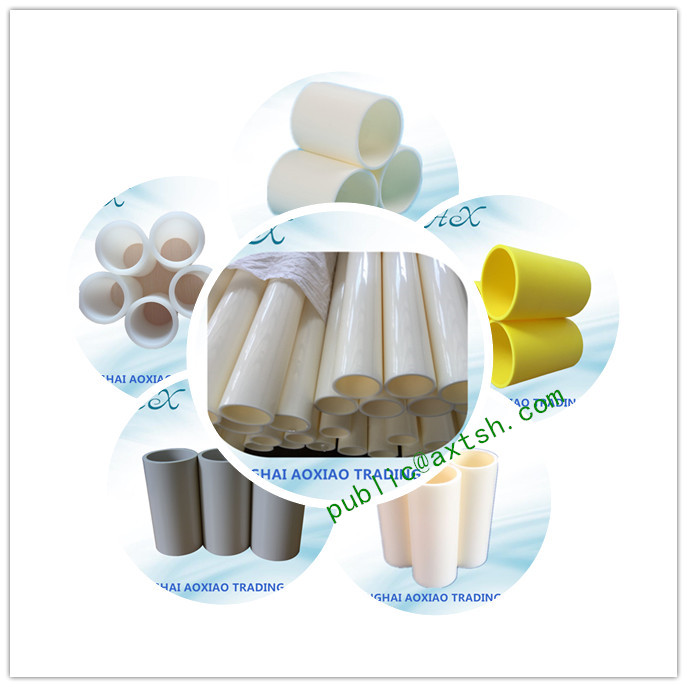

ABS Plastic Tube Core for Film

The following points are summarized.

1. The mold ledger is well established, and the production conditions, peripheral equipment, and mold and machine records must have corresponding relationships.

Ten minutes on stage, ten years off stage. Turning molds is a concentrated expression of what our technicians usually do.

The mold ledger is the use history of each set of molds, the corresponding machine, and the corresponding peripheral equipment. These can be prepared in advance when the mold is transferred, and it can also be discovered in advance which equipment is in use and coordinated in advance. Find. This can reduce the waiting time for the die. Our company also sells China BOPA PE Pipes Film.

How to quickly produce qualified products after mold transfer? This requires us to have a complete management of condition records. There must be a record every time the machine is adjusted, and this record must follow the machine. With perfect conditions, you can call up the conditions immediately after the mold transfer, and carry out pattern production according to the conditions.

Under normal circumstances, the machine has not changed much, the mold has not been produced on this machine for a long time, and no problem will occur without mold repair. The first inspection is synchronized and can be produced directly. This reduces tuning and waiting time.

2. Complete the work that can be completed before the mold transfer, and reduce the work during the mold transfer.

To achieve 100 tons of transfer speed, it is necessary to prepare some of the operating time on the large machine and the large mold before the transfer, so as to reduce the operating time during the transfer. The operations that can be done in advance can only be performed on the mold or the machine, and the operations follow the mold or the machine.

3. Good communication in all aspects of production, make preparations for mold transfer in advance.

Production often changes temporarily due to planned changes. Good communication can avoid the transfer of molds that should not be transferred, and avoid situations where molds and equipment cannot be found everywhere.

Our company also has ABS Plastic Tube Core for Film on sale, welcome to consult.