What Are The Basic Factors That Affect The Shrinkage Of Plastics? 1

After the plastic is taken out from the mold and cooled to room temperature, the characteristic of dimensional shrinkage is called shrinkage. Since this shrinkage is caused not only by the thermal expansion and contraction of the resin itself, but also by various molding factors, the shrinkage of the molded part after molding is called molding shrinkage.

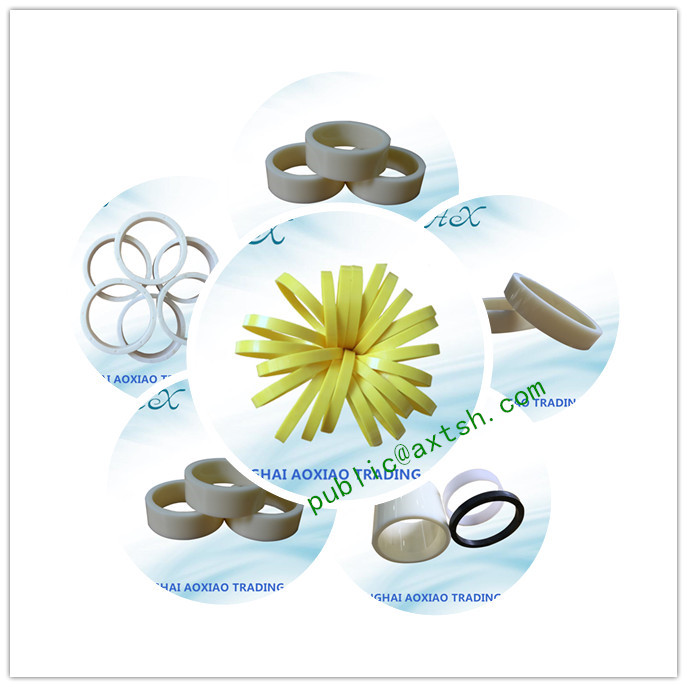

The shrinkage of plastic parts has a great impact on the quality of the product, the design and manufacture of the mold. For this reason, the factors affecting the shrinkage rate of the plastic parts should be deeply understood. As a 3 Inch Plastic Stopper Wholesaler, we think there are the following.

1) The pressure of the forming pressure melt after entering the mold cavity is quite high. This pressure increases the density of the melt. Therefore, the greater the pressure in the cavity, the smaller the shrinkage after molding, the amorphous plastic and The shrinkage rate of crystalline plastics decreases with the increase of internal pressure, which is linear and curved.

2) Injection molding temperature When the plastic changes from solid to liquid, it is caused by heating. During the heating process, the volume of the plastic material will expand and the shrinkage of the plastic parts will increase. On the other hand, due to the increase of temperature The time for closing the gate is prolonged, the melt entering the cavity is increased, the density is increased, and the shrinkage rate is decreased. The result of the simultaneous action of the two is generally that the shrinkage decreases with increasing temperature.Our company provides Plastic Core For Film. Welcome to contact us.