What is the Principle of Foam Injection Molding?

Foamed plastic is a plastic with a thermoplastic or thermosetting resin as

its matrix and numerous micropores inside. Foaming is one of the important

methods of plastics processing. The foam plastic obtained by plastic foaming

contains two kinds of gas and solid-gas and solid. The gas exists in the foam in

the form of cells. Cells that are isolated from each other are called closed

cells, and those that communicate with each other are called open cells. There

are two types of closed-cell foam and open-cell foam. The open or closed cells

of the foam structure are determined by the properties of the raw materials and

their processing technology.

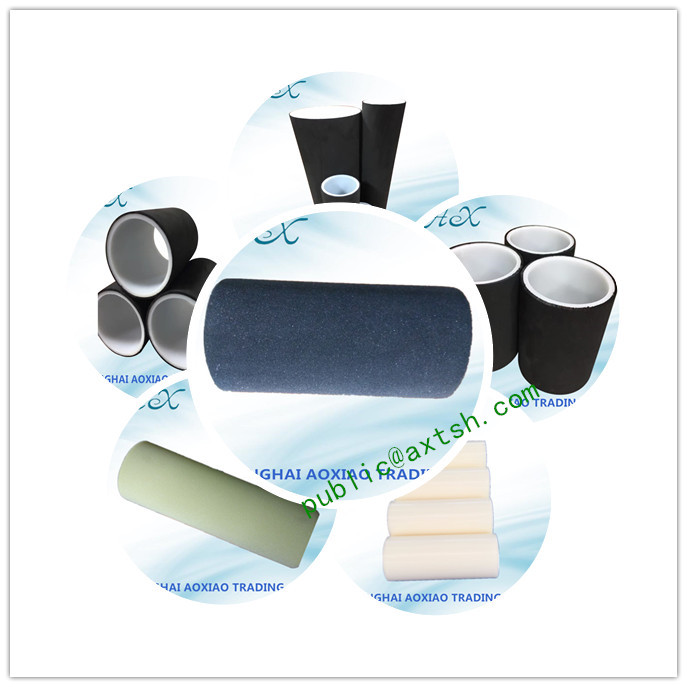

PE Plastic Tube Core

The technology of plastic foaming has a long history.

Today, basically all plastics, including thermoplastics and thermosets, can be foamed into foam. The industrial preparation methods include: extrusion foaming, injection foaming, molding foaming, calendering foaming, powder foaming, spray foaming, and the like. Among them, injection foaming is one of the most important molding methods. Here, the focus is on injection molding foaming.

Foam molding principle

Plastic foaming methods can be divided into physical foaming methods and chemical foaming methods according to the foaming agent used. As a BOPA PE Pipes Film Supplier, share with you.

Physical foaming

In simple terms, there are three methods to make plastic foam by physical methods:

(1) Dissolve the inert gas in the plastic melt or paste under pressure, and then release the gas under reduced pressure, thereby forming pores and foaming in the plastic;

(2) Foaming by evaporating the low boiling point liquid dissolved in the polymer melt and foaming it;

(3) Hollow spheres are added to plastic to form a foam and foam.

The cost of the physical foaming agent used in the physical foaming method is relatively low, especially the cost of carbon dioxide and nitrogen is low, and it is flame retardant and non-polluting, so it has high application value; and there is no residue after the foaming of the physical foaming agent. It has little effect on the properties of foamed plastics. But it requires a special injection molding machine and auxiliary equipment, which is technically very difficult.

Chemical foaming

The chemical foaming method uses chemical methods to generate gas to foam plastics: the chemical foaming agent added to the plastic is heated to decompose and release the gas to foam; in addition, the plastic components can be used to chemically interact with each other. The released gas reacts to foam.

In short, no matter which plastic material is selected or which foaming method is used, the foaming process generally goes through the stages of bubble core formation, bubble core expansion, and foam solidification.

Our company also has PE Plastic Tube Core on sale, welcome to consult.