Do you know how PVC is Injection Molded?

As a PVC Plastic Tube Core Manufacturer, share with you.

Because of its low price, PVC materials are inherently anti-inflammatory, strong and strong, and have good chemical resistance. The shrinkage rate is 0.2-0.6%. Products are increasingly used in electrical appliances, machinery, construction, daily necessities, toys, and packaging. According to the characteristics of the PVC material, the analysis of the injection molding process of the product is as follows:

The characteristics of PVC material

Poor thermal stability of PVC, molding temperature close to decomposition

temperature, poor fluidity, easy appearance of defective defects, poor heat

resistance of PVC material, the easiest to scorch, generate acid gas and corrode

the mold, can be plasticized during processing Additives to increase its

fluidity, generally need to add additives to use, its strength, electrical

insulation, chemical resistance is good.

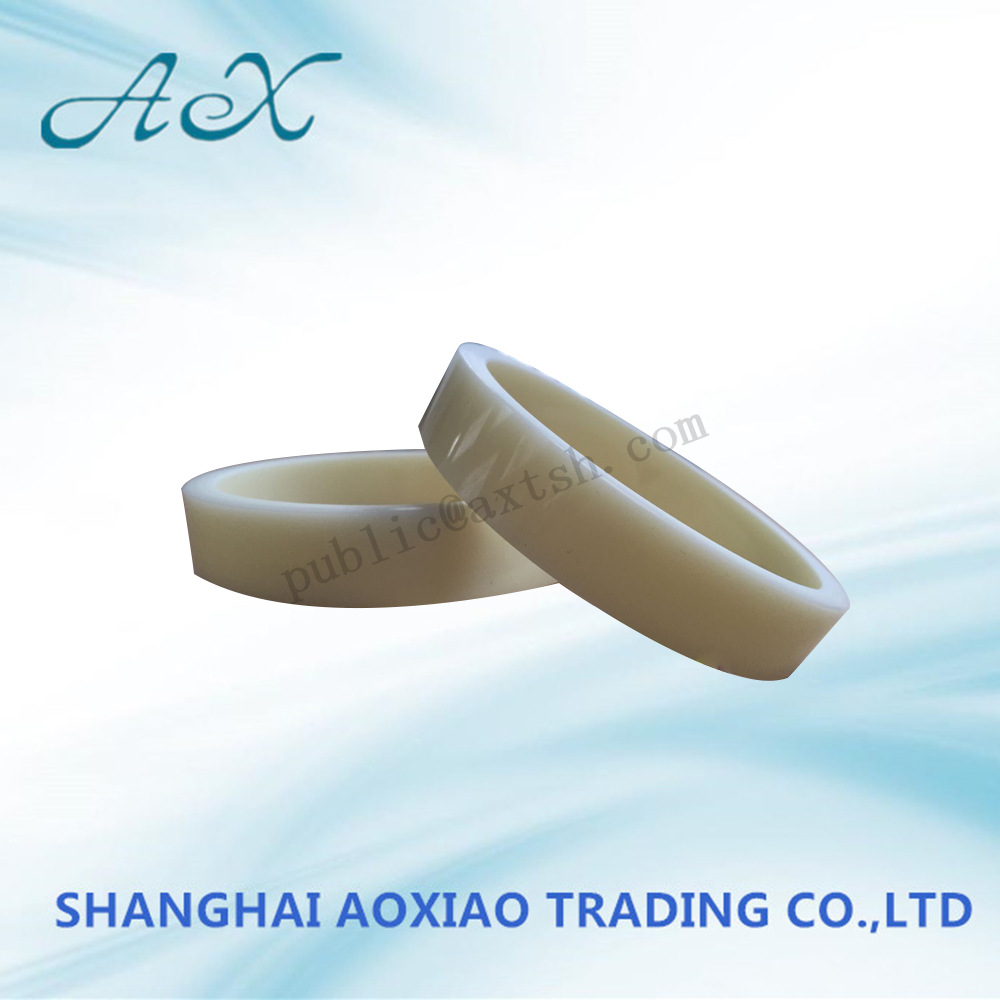

PVC Packing Plastic Tube Core

Design of mold and gate

In order to shorten the injection molding cycle, the shorter the nozzle, the better. The cross section should be round. The diameter of the nozzle mouth should be at least 6 mm. It should be tapered and the inner angle should be 5 degrees. It is better to add cold material wells. Wells prevent poorly-melted semi-solid materials from entering the mold cavity, and these materials will affect the surface modification and product strength.

The draft angle should be between 0.50 and 10 to ensure that there is sufficient exhaust equipment in the cavity. The commonly used vent hole size is 0.03-0.05mm deep and 6mm wide, or the clearance around each ejector pin is 0.03-0.05 mm. The mold should be made of stainless steel or hard chromium plated.

The PVC molding process

PVC is a heat-sensitive plastic. Overheating or excessive shearing will cause decomposition and spread quickly, because one of the decomposition products (such as acid or HCI) will catalyze, which will cause the process to further decompose, and acidic materials will erode the metal and change The formation of a depression will cause the protective layer of the metal to peel off, causing rust, which is more harmful to the human body.

1. Screw dunnage: The screw dunnage is between 2 and 3mm, and large opportunities are greater.

2. Injection volume: the actual cylinder residence time cannot exceed 3 minutes.

3. Barrel temperature setting:

The temperature provided can only be used as a reference, and appropriate adjustments can be made according to the actual situation of the machine and raw materials. It may also exceed the recommended range.

4. Barrel retention time: Under the temperature control of 2000C (rubber), the barrel retention time can exceed 5 minutes at most.

5. Injection speed: the injection speed should be slow, otherwise excessive shearing will degrade the material. When using UPVC to produce extremely smooth thick-walled products, multi-stage injection speed should be used. If light brown stripes are emitted from the gate, Indicates that the shooting speed is too fast.

6. Back pressure: The commonly used surface value is 5 bar. Increasing the back pressure is beneficial for color mixing and exhaust, but the lower the back pressure, the better.

Our company also sells PVC Packing Plastic Tube Core, welcome to consult.