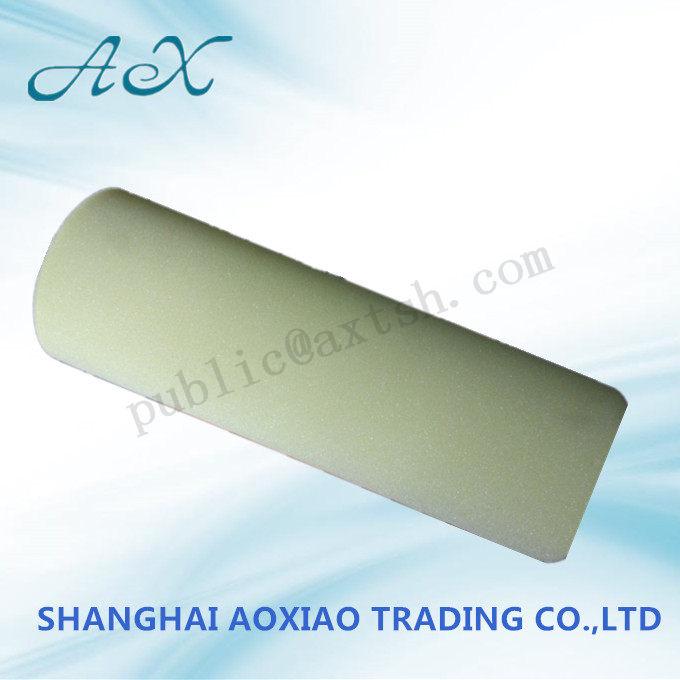

PE plastic tube core

Plastic Tube With Foam:

ID: From 1 to 6 inches

The raw material: PE,PP,PVC,ABS

Width: according to customer requirements for the length of cut

Advantages: the foam tube can cushion the direct contact between the product and the core, and avoid the occurrence of crease, wrinkle and bulge in the film near the core position.

| Product Description:Plastic Pipe /Tube /Core | |||||||

| Material: PP, ABS, PVC ,PE ,NYLON | |||||||

| Payment Terms: | |||||||

| Loading Port: Shanghai China | |||||||

| Samples Leading Time: 3-7 days | |||||||

| Delivery Time: Within 7-15 days after ur payment | |||||||

| Payment: L/C, T/T, paypal | |||||||

| CHARACTERISTICS | |||||||

| a. Good Strength | |||||||

| b. Smooth Surface Appearance | |||||||

| c. High Cleanliness | |||||||

| d. Low Shrinkage | |||||||

| e. Reusable | |||||||

| f. Feature High UV-resistant,super solarization resistant,Good aging resistant | |||||||

| APPLICATIONS | |||||||

| a. High protective film winding. | |||||||

| b. Lithium battery diaphragm winding. | |||||||

| c. Solar back winding. | |||||||

| d. Film turnover tube. | |||||||

| e. Chemical corrosion transmission tube. | |||||||

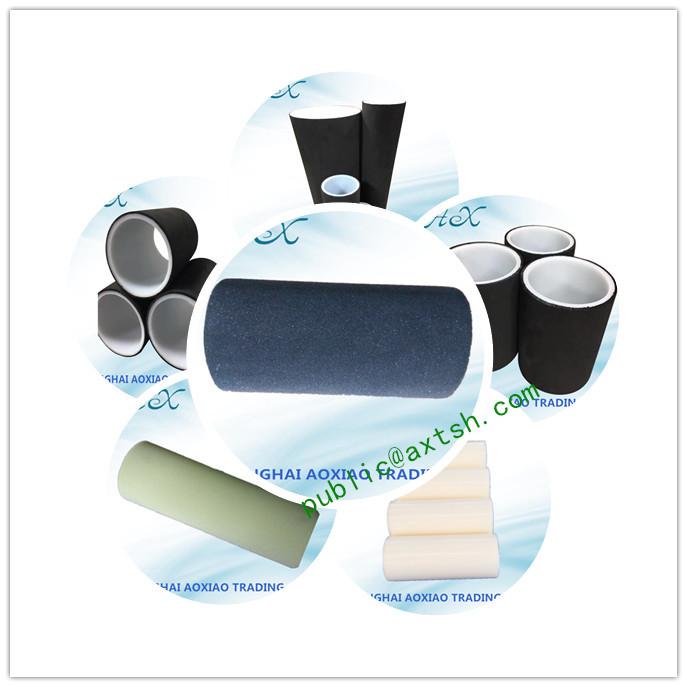

| PRODUCTS | |||||||

| PACKAGE & DELIVERY | |||||||

| Packaging Details: | |||||||

| 1. General Packaging: Cutton packing with plastic film inside. | |||||||

| 2. Material: Good quality polyethylene plastic film. | |||||||

| 3. Quantity Packed:30 Pcs Pipes Per Carton | |||||||

| 4. Carton Size: Customized printing and based on actual weight and volume. | |||||||

| Delivery Details: | |||||||

| 1. By Express (3-7 days): Suitable for urgent order or small quantity order. | |||||||

| 2. By Sea (15-30 days): Suitable for regular mass production. | |||||||

| 3. By Air (4-5days): From airport to airport, use for samples and retail products. | |||||||

| OUR SERVICE | |||||||

| 1. Sample Service: We could offer free samples and you need to pay freight cost. | |||||||

| 2. About Payment Terms: W.U., T/T, L/C, Paypal etc.. | |||||||

| 3. What information should we need for quotation? | |||||||

| a. The export port and trade terms. | |||||||

| b. The packaging details. | |||||||

| c. Kinds of pipes/materials/thinkness/length/specifictions etc. | |||||||

| d. Customized size demand, if you can provide photo or artwork is better. |

About Plastic Pipe Core

Manufacturing method of plastic pipe core

There are many production materials forplastic core, such as plastic, PVC, PE, HDPE etc. Among them, PVC is common. This material has a wide range of applications, so what is PVC material? The production method ofplastic core What is it? Let me introduce it to everyone.

The utility model relates to a pipe material, in particular, it relates to a roll core pipe.

Theplastic core is a component used to curl a variety of sheeting-like products such as sheeting, tape or paper to facilitate the storage and transportation of the product.

The material of the rollplastic core is different, according to the product to be rolled, including paper rollplastic core, plastic rollplastic core and metal rollplastic core. Plastic rollplastic cores are widely used for their advantages such as light weight, smooth surface, wear resistance, and resistance to deformation.

Plastic die benefits

Reduce losses

High strength, not easy to deform, stable physical properties, effectively prevent the wrapped sheeting from being damaged due to the deformation of the winding core. High processing accuracy and good surface finish can increase the usage rate of the sheeting, and solves the disadvantages of the traditional shaft tube that has to rely on the wrapped sheeting to fill the gap due to the rough surface.

2. Large carrying capacity

The high longitudinal strength and ring rigidity make it characteristic of high load bearing.

3. Reusable

Corrosion resistance, impact resistance, not affected by humidity, acid and other environmental factors.

4. Cut clean (except PVC pipe)

Slitting without cutting, suitable for dust-free workshop environment

5. Repairable

Classification of plastic core

The characteristics of PPplastic core are non-corrosion, abrasion resistance, non-scaling, reduction of vibration and noise, and anti-freeze cracking (pp coreplastic core generates frost cracking at low temperature exceeding -20 ℃, and the high temperature working environment only needs to exceed 70 ℃ Decompose, use temperature is -20 ℃ to 70 ℃), prevent dew condensation, less heat loss, simple installation and long service life. There are three types of connection methods: welding, end welding, and different material takeover.

PE rollplastic core has good abrasion resistance. A comparative experiment of the wear resistance of polypropylene pipe and steel pipe shows that its wear resistance is 4 times that of steel pipe. It has good resistance to stress cracking and precision: PE coil core pipe has low notch sensitivity and high shear strength. It has outstanding traceability and environmental stress resistance. Long service life Polyethylene pipes have high molecular weight, good stability and aging resistance. Under normal working temperature and pressure conditions, the service life can be more than 50 years.

ABS resin can be blended with a variety of resins into blends, such as PC / ABS, ABS / PVC, PA / ABS, PBT / ABS, etc., resulting in new properties and new application areas, such as: mixing ABS resin and PMMA, can Manufacture of transparent ABS resin.

About us

The manufacturer develops a variety of environmentally friendly new materials made of sheeting packaging rollplastic cores according to the high purification request of the market. The company has a full range of materials. The polymer materials used are PE, PP, ABS, HIPS, PVC, PU, HDPE etc. The tube greatly improves the strength, and also get the solutions of the problems of the paper tube's surface being frizzy and not smooth, and the defects of paper dust. Among them, the PE pipe has good toughness, and can be randomly cut with a rolled sheeting to ensure no chips and dust, convenient use and improved efficiency. For the majority of electronic technology industrial area, China protective sheeting, industrial adhesive tape companies are welcome. Has applications in a large number of manufacturing sheetings, there are many types of sheetings, including multi color ,thickness and sizes PE sheeting, PET sheeting, BOPP sheeting, polyester sheeting, polyimide sheeting, PVC sheeting, fluoroplastic sheeting, PE, EVA sheeting, acrylic foam , Cotton paper, textured paper, aluminized sheeting, aluminum foil, copper foil, etc.

In recent years,we have made great progress in business development relying on our efficient management and high-quality service,we have extended our business to southeast Asia,Europe and America and we have established long-term business relationship with our clients from many countries such as America,Canada,Mexico,Sudan,Thailand,Malaysia,Philippines and Indonesia. As a China manufacturer of ABS Plastic Core. We have a high-tech work shop. We have a complete quality management system. Choose our HDPE plastic tube core, you can be get most careful and thoughtful service, we can provide you international standard and certified的plastic roll,tube and core, which you need and requset!