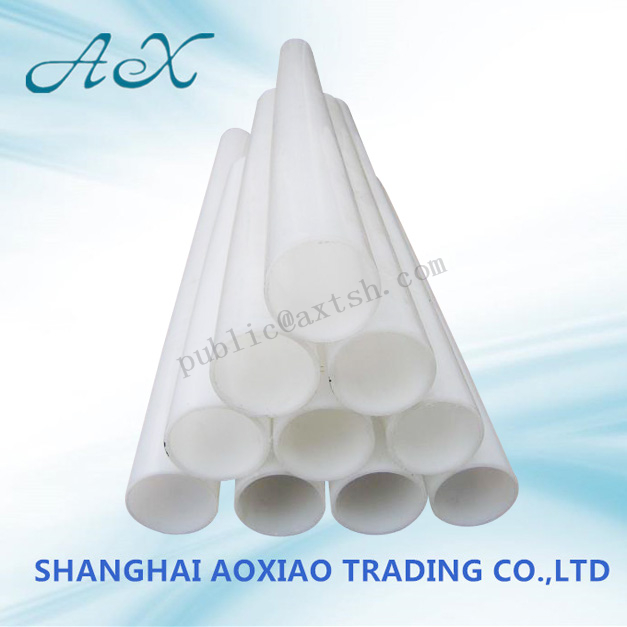

Production process of PE Plastic Tube Core

Production process of PE Plastic Tube Core

As a Tapes PE Pipe Supplier, share the information with you. The plastics industry is developing rapidly and the quality is constantly improving. The plastic pipe industry mainly based on PVC-U pipe, PE pipe and PP-R pipe has been initially formed. Among them, PE pipe is widely used in building water supply, building drainage, buried drainage pipe, building heating, gas transmission and distribution, gas transmission pipe, electrical and telecommunication protective casing, industrial pipe, agricultural pipe, etc. . It is mainly used in urban water supply, urban gas supply and farmland irrigation.

The specific steps of the production process of PE plastic tube core are as follows:

1. Mixing and drying

The function of mixing material drying is to stir, dry and mix the PE resin and the color masterbatch to obtain uniform raw materials.

2. Plastic extrusion

The raw materials are fed from the hopper into the extruder, and the solid particles gradually change to a highly elastic state, and then gradually change from a high elastic state to a viscous fluid under continuous transport, compression, melting and homogenization, and continuously extruded.

3. Mold forming

At the proper temperature, the material extruded from the extruder enters the die from rotary motion to linear motion through the filter plate. After spiral splitting, it is fused and compacted into a tubular parison in the forming section, and finally extruded from a die.

4. Cool setting

The heat pipe blank extruded from the mold is shaped and cooled by a sizing sleeve vacuum sizing box under a negative pressure state, and then the inside of the pipe is gradually cooled through a spray forest cooling box, so as to solidify and shape the whole.

5. Cutting

Under the control of the meter counter wheel, the fixed length cutting of the tube is completed by the planetary cutting machine.

6. Stacked packaging

The cut pipe is pushed to the turntable and transported after inspection and

packaging.

China BOPA PE Pipes Film

The above are the specific steps in the production of PE Plastic Tube Core. When producing PE plastic tube core, the above steps are indispensable. But also pay attention to the following points in the production operation:

1. Precautions for loading machine operation

The suction time should not be too long; clean the filter frequently; monitor whether the micro switch is normal.

2. Precautions for dryer operation

(1) Turn on the fan first and then turn on the heating.

(2) The best drying effect can be achieved when the barrel is full.

(3) The drying temperature of PE material is about 80 ° C.

(4) The temperature control meter shows the difference between the actual temperature at the set temperature. When the displayed temperature is zero, the actual temperature is consistent with the set temperature.

(5) Bimetal thermometer working principle: Use two materials with different expansion coefficients to measure the temperature according to the degree of deformation.

(6) Control the running direction of the wind.

(7) The air inlet must not be closed.

Under normal circumstances, if you want to produce qualified PE pipes, you need to go through the production steps and processes of these PE pipes. In addition, enterprises can also optimize their own production popularity according to their actual conditions, so as to achieve the best quality of PE pipe production. Poly PE pipe has simplified the original production process and implemented its own research and development production process, so that the quality of the produced PE pipe is better than other brands of PE pipe.

Our company also has China BOPA PE Pipes Film on sale, welcome to consult.