Why do Bubbles Occur During the Processing of Plastic Products?

As a BOPA PE Pipes Film Supplier, share with you. Bubbles often occur at the last seam of the plastic product or the thicker part of the product. The surface cooling of the product first in the model, when the outer surface has cooled, the central part is still in a hot state.

The center part shrinks when it cools, and the plastic surface has cooled, so

it can only be contracted by itself to form bubbles. There are many thick parts

without bubbles when they are released from the mold, but after dozens of

seconds, bubbles appear in the center.

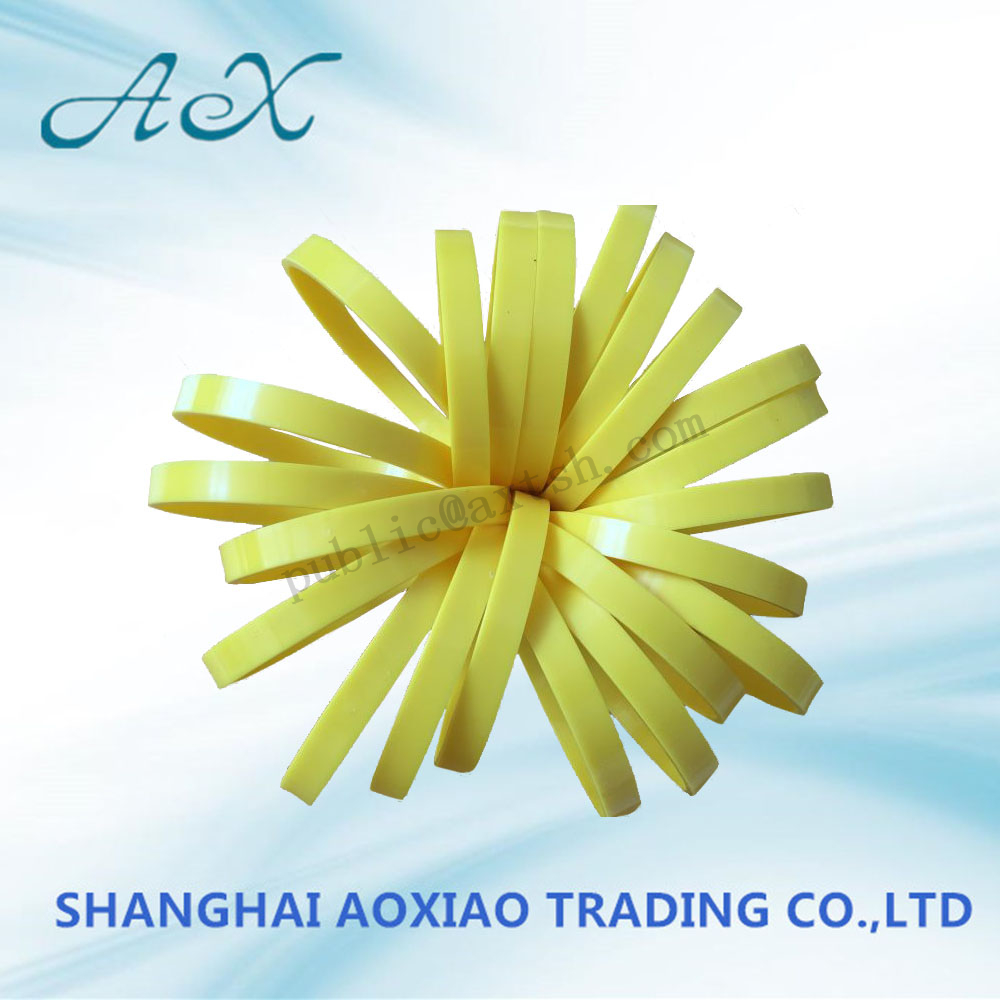

PE Plastic Tube Core

There are several cases of air bubbles, the phenomenon is different, the reason is also different, as described below:

Q: The thicker product has a fat and bulging surface, and there are bubbles at the sawing section. The reasons may be:

The injection speed is too fast, which entraps air and cannot be excluded, forming bubbles.

Too much or too little feed, too high injection pressure will also cause this phenomenon, such as proper adjustment of the feed will improve this phenomenon.

The cooling time is too short, the solution can be cooled with cold water and cold die outside the machine.

There is a phenomenon of decomposition of black lines in the product, which is caused by excessive temperature. If the situation is not serious, the temperature can be lowered properly. If the entire barrel decomposes, it must be disassembled and cleaned.

This phenomenon can also occur when the mold gate is too small and the exhaust is poor.

Q: The solid products are hollow and blackened

When the solid product is molded, the injection pressure should be low and the injection speed should be slow. Otherwise, the air will be entrapped in the product by friction and scorching under high pressure, so that there are black voids in the product. Therefore, properly reduce the injection pressure and injection speed, the cavity phenomenon will disappear. You can also check whether the amount of feed is excessive, and appropriate reduction of some amount of feed is also beneficial to improve this phenomenon.

When the thickness of the plastic product is different, there are small bubbles in the thicker part of the product, or a large black bubble is wrapped in the extra thick part of the product

When molding several products with different shapes at the same time, it must be noted that the size of each gate should be equivalent to the weight of the product, otherwise, thick products are prone to air bubbles. At the same time, we must pay attention to the exhaust of the mold. The products often left on the front mold make the exhaust more difficult, and the above phenomenon is easy to occur.

This phenomenon can be improved by modifying the mold or increasing the holding time and cooling time, and the insufficient pressure of the cross-section of the pregnancy supplement. More importantly, when designing products, try to avoid products with extra thick parts.

Our company also has PE Plastic Tube Core for sale, please contact us.