What Issues Should be Paid Attention to in the Pre-Plastic Stage?

What Issues Should be Paid Attention to in the Pre-Plastic Stage?

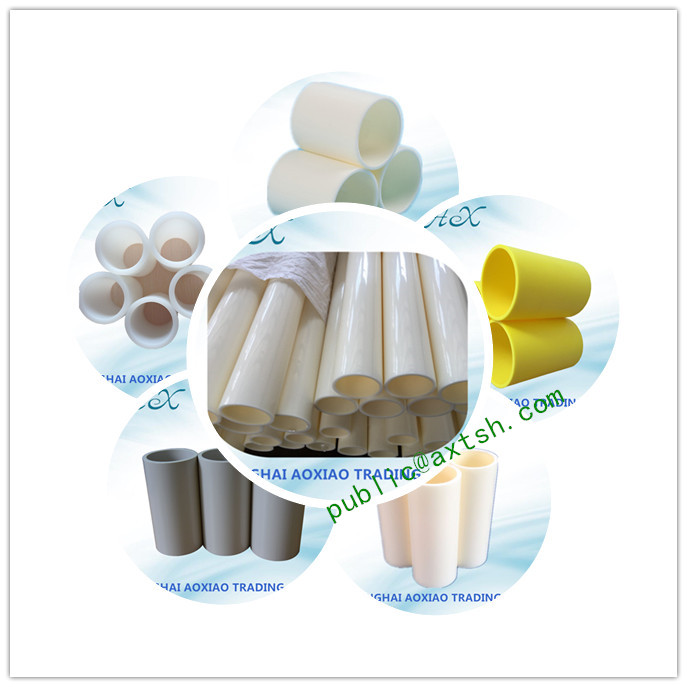

As an ABS Plastic Tube Core Supplier, share with you.

ABS Plastic Tube Core

1. Screw speed

1. The melting of plastic is mainly due to the heat generated by the rotation of the screw, so the screw speed is too fast, it has the following effects:

Thermal decomposition of plastics;

Shortening of glass fiber (plus fiber plastic);

The wear of the screw or heating cylinder is accelerated.

2. The speed setting can be measured by its circumferen-tial screw speed: circumferential speed n * d * π

Generally, for low-viscosity plastics with good thermal stability, the peripheral speed of the screw rod rotation can be set to about 1m / s, but for plastics with poor thermal stability, it should be as low as about 0.1.

3. In practical applications, we can reduce the screw speed as much as possible, so that the rotary feeding can be completed before the mold is opened.

Second, back pressure

1. When the screw rotates and feeds, the pressure accumulated by the melt advancing to the front end of the screw is called back pressure, which can be adjusted by adjusting the oil return pressure of the injection hydraulic cylinder during injection molding. :

Melt melts more evenly.

The toner and filler are more evenly dispersed.

Let the gas exit from the blanking port.

The measurement of the feed is accurate.

2. The level of the back pressure is determined by the viscosity and thermal stability of the plastic. Too high a back pressure increases the feeding time, and it is easy to cause the plastic to overheat due to the increase of the rotating shear force. Generally, 5 ~ 15kg / cm2 is suitable.

3. Retreat

1. After the rod feed is completed, the screw can be properly withdrawn, and the pressure of the melt at the front of the screw can be reduced. This is called loosening, and its effect can prevent the nozzle from dripping.

2. Insufficient loosening is easy to stick the main channel; too much loosening can suck in the air and cause gas marks on the molded product.

4. Modification of plasticizing parameters

Confirm whether the back pressure needs to be adjusted;

Adjust the screw speed to make the metering time slightly shorter than the cooling time;

To confirm whether the metering time is stable, you can try to adjust the temperature gradient of the heating ring;

Check whether there is dripping in the nozzle, whether there is pig tail or sticky mold in the main channel, and if there is any gas mark in the finished product. Adjust the temperature of the nozzle part or the loosening distance appropriately.

5. Multi-stage pressure maintaining and multi-stage rate of fire activities

1. Generally speaking, without affecting the appearance, the injection should be based on the principle of high speed, but it should be carried out at a lower speed before passing through the gate and switching the holding pressure;

2. The holding pressure should be gradually reduced to avoid the residual stress in the molded product being too high, which makes the molded product easy to deform.

Our company also has ABS Plastic Tube Core for Film for sale, please contact us.